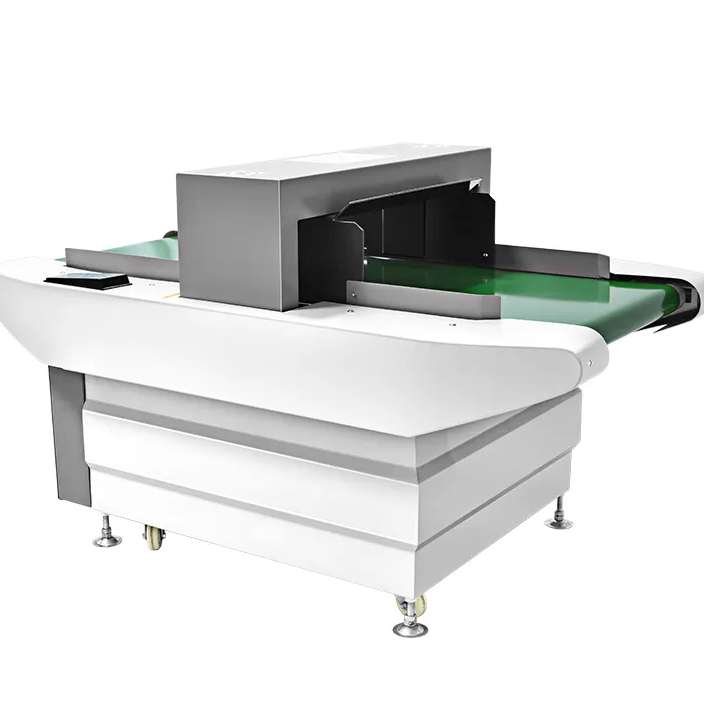

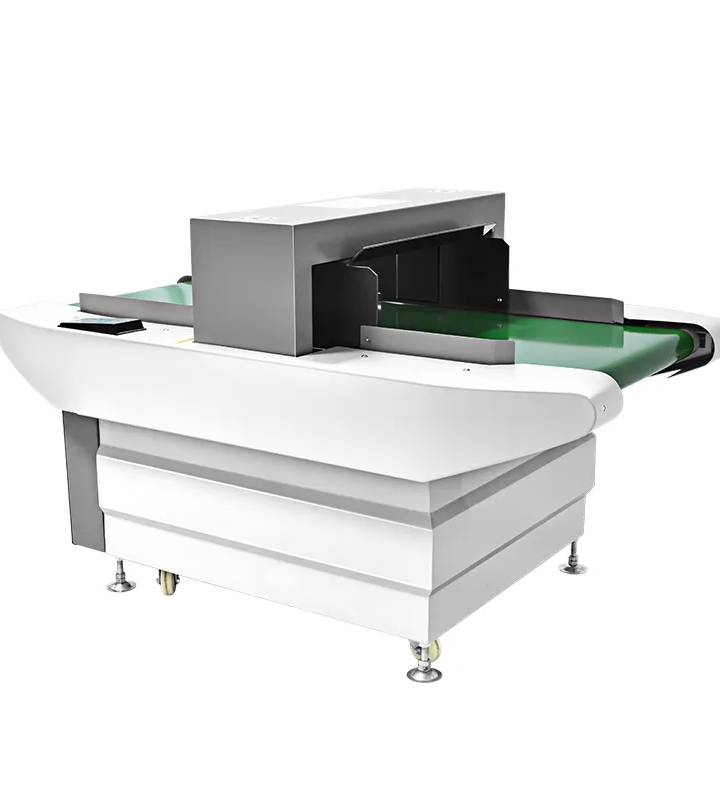

Our state of the art needle detecting machine is made to accurately and consistently identify the presence of broken needles or other metallic contaminants in textiles or garments. This strong and effective equipment is a must in the manufacturing of any form of clothing, bedding or even toys. It lessens defective products from getting to the market as it scans materials for such with a high degree of accuracy preventing the tarnishing of one`s name and satisfying the safety expectations.

This technologically advanced system is capable of meeting all necessary safety requirements because the smallest metal fragment should be present anywhere. It has a light touch screen and basic buttons allowing for such simple formulation and changing of parameters that are easily realized in such a high turnover production environment. Portable and highly effective, great peace of mind is planted in all our nettle detectors as they can be installed in any production line without the fear of endangering users of the products.

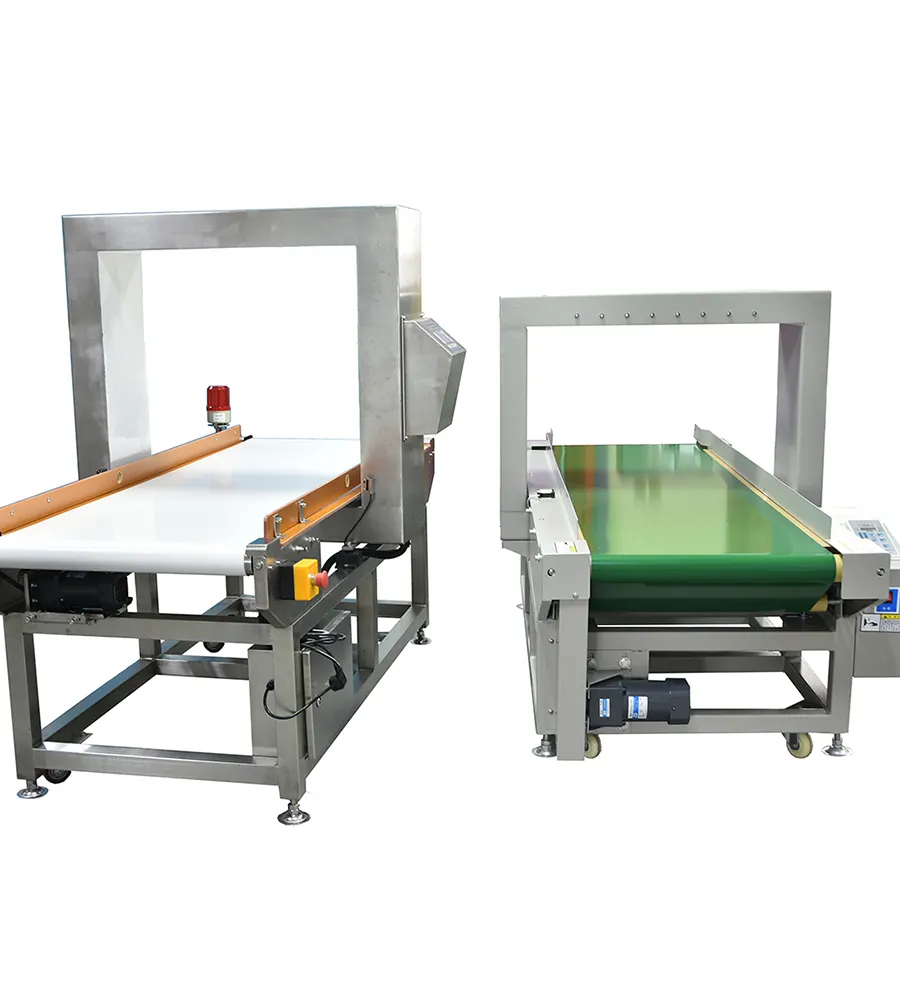

Not limited to textile applications only, needle detectors have an important application in food production These needle detectors avoid any harm from reaching consumers by first detecting metal pieces embedded in food products These detectors are intended to examine items that pass along the production line for contamination. As the safety of food products improves more and more, here comes the importance of the needle detectors for manufacturers who want to remain within the requirement of the industry and do not put their consumers at risk.

Needle detectors perform an important role in the product quality in companies such as garments and textile industries These devices locate missing broken needles or metal scrapes which can cause great dangers to the consumers and workers. Needle detection systems assist in garment inspection during the manufacturing process and help manufacturers ensure maximum safety by eliminating contamination of the items launched into the market. Further, using needle detectors in production lines reduces the likelihood of incurring the costs associated with product recalls due to pollution of the products which promotes efficiency in the factory processes.

The introduction of needle detectors in the nursery and other quality control processes enhances the level of safety of the textile products The scanners apply modern technology to detect the tiniest metal fragments that might have been left inside the garments after the production process Needle detectors are such instruments that are able to detect very even small fragments of broken needles inside countable parts of the fabric This helps in ensuring that every individual garment meets the required safety standards before it is packed and sent to the retailers hence needle detection plays a major role in the achievement of high quality of production standards.

Guangdong Yiwan Testing Technology Co., Ltd., situated in Dongguan City, enjoys strategic transportation advantages. As a comprehensive enterprise encompassing product design, R&D, sales, and service, we specialize in manufacturing and marketing metal separators, checkweighers, food metal detectors, wheel sorters, and weight sorting machines.

A needle detector is used to detect broken or stray needles in textile products, ensuring safety and quality control. It is commonly used in the garment and toy manufacturing industries to prevent any hazardous metal fragments from reaching consumers, particularly in children’s products.

A needle detector works by using magnetic sensors to detect ferrous metals, such as broken needles, in products. When a metal object passes through the machine, it triggers an alarm, allowing operators to remove the item before the product moves forward in production.

Needle detectors are essential in industries such as garment manufacturing, toy production, and food processing. They help ensure safety by identifying any metal contamination in finished goods, particularly in products that are intended for children or sensitive consumers.