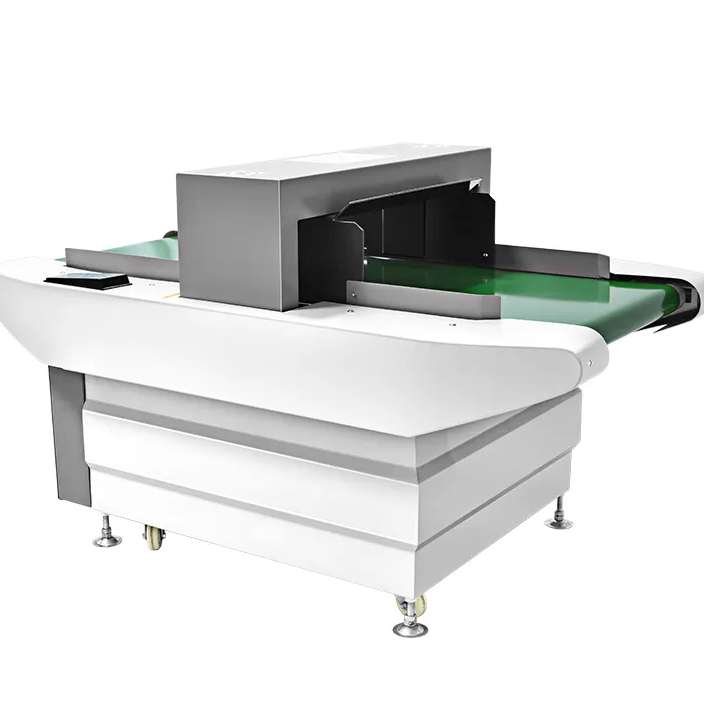

In the garment industry, quality assurance and product safety are of utmost importance. A long time to this purpose needle detector machines. These machines are instrumental in detecting foreign materials especially needles that can become dangers for both the producers and the end users. As a recognized brand in the field, Ywan Test offers solutions designed specifically for the garment industry.

Needle Detection Importance

There are many reasons that make needle detection necessary. The first and the most important reason is to protect the consumers from cut injuries. Garments which have protruded or retained needles can be damaging and can lead to litigations and tarnishing of the brand image. By use of needle detector machines, manufacturers are able to greatly minimize the occurrence of such cases.

Looking at the bigger picture in garment manufacture

In as much as needle detector machines can be employed to prevent injuries, these machines can also make sure that quality control is enhanced in the course of production of garments. These machines are manufactured to be very easy to be used in production lines where the final products are checked within a very short time and with a high degree of precision. Using Ywan Test machines have also allowed even the slightest of needles to be detected before the garment is made available to consumers.

Industry Standards Observance

In many areas, there are strict rules and regulations concerning the safety of products in the garment industry. Because of their advanced features, needle detector machines are beneficial to manufacturers as they wish to avoid incurring hefty penalties and also ensure their goods meet safety standards. Ywan Test has machines that go beyond needle detection and even printing detailed reports which assist companies in retaining compliance records.

Efficiency

Long term investment in needle detector machines can be economically beneficial. If injuries and product recalls are avoided, manufacturers can cut substantial sums of depreciation expenses and liabilities. Ywan Test machines are built of efficiency, and with these machines downtime is drastically reduced and therefore production processes remain efficient.

In summary, needle detector machines are more of a necessity than an accessory within the garment industry. They promote safety, foster quality control and ensure industry regulation adherence. Ywan Test is a credible company that supplies these kinds of machines for protection of manufacturers’ products. Safety measures such as needle detection should be encouraged since they not only protect consumers but also smoothen various business operations.