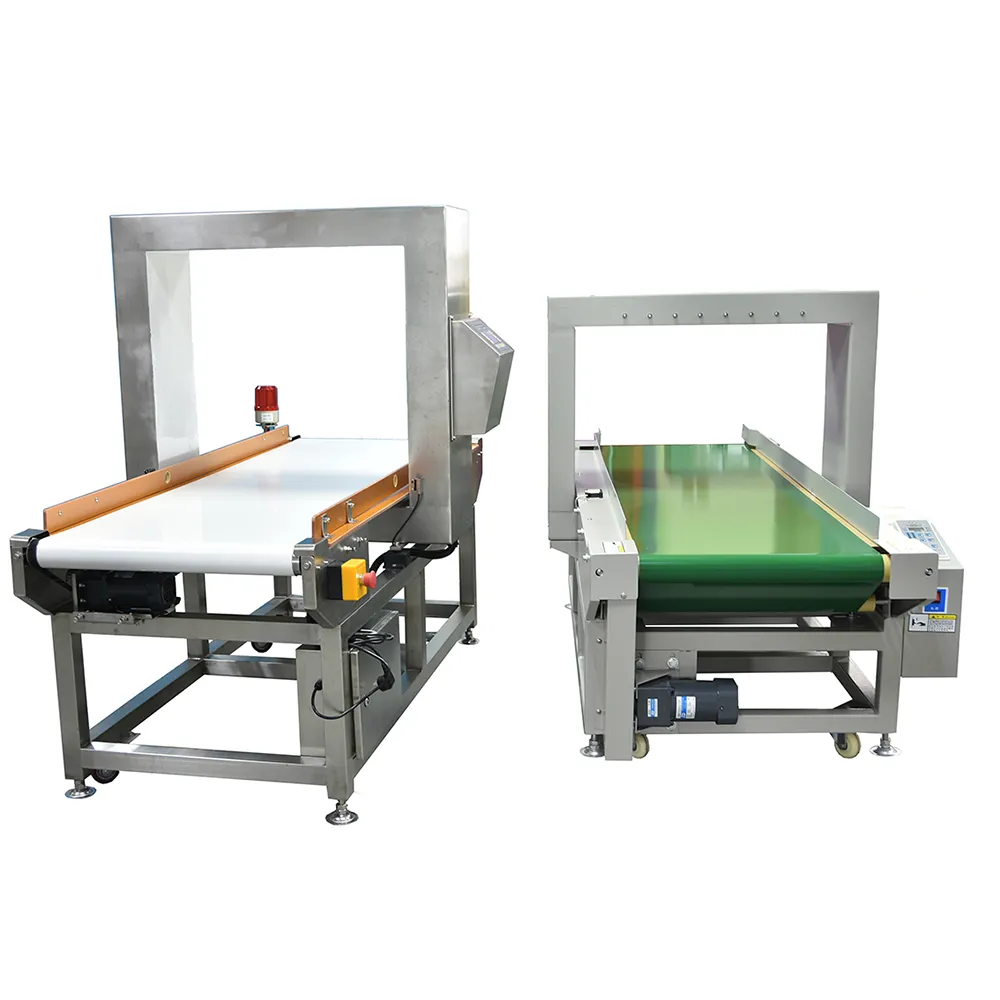

Оёдлын шалгалтын машин нь бүтээгдэхүүний аюулгүй байдал, чанарт анхаарал хандуулж байгаа учраас бараг бүх салбарт чухал ач холбогдолтой болсон. Эдгээр машин нь бүтээгдэхүүний чанар болон хэрэглэгчдийн аюулгүй байдлыг алдагдуулах боломжтой оёдол эсвэл хурц металл хэсгүүд зэрэг аюултай зүйлсийг илрүүлэх, гаргах боломжийг олгодог. Энэ нь аюулыг зайлсхийх зорилгоор хийгддэг. Инжекцийн илрүүлгийн системийн салбарт нэр хүндтэй брэнд болох Ywan Test нь оёдлын шалгалтын машин үйлдвэрлэлд чанарын баталгааг нэмэгдүүлэх зорилготой.

Цагаан арьсын шалгах машинуудыг ашиглан ялгаатны дүрс боловсруулах процедуур

Оёдлын шалгалтын машин нь чанарын хяналтын салбарт маш чухал юм. Эдгээр машин нь үйлдвэрлэгчдэд брэндийн нэр хүндийг хамгаалах, хэрэглэгчдийн итгэлийг хадгалахад чиглэсэн аюулгүй байдлын стандартуудыг хангахад тусалдаг. Ийм машинуудаар үйлдвэрлэлийн шугамд нэгдсэнээр компаниуд итгэлээ нэмэгдүүлж, зах зээлд гаргахдаа бүтээгдэхүүнүүд нь ямар ч бохирдолгүй байхыг баталгаажуулж чадна.

Оёдлын шалгалтын машин хэрхэн ажилладаг вэ

Оёдлыг шалгахын тулд Ywan Test нь хамгийн жижиг металлын объектыг олоход зориулсан орчин үеийн арга хэрэгсэл ашигладаг. Жишээлбэл, ийм төхөөрөмжүүдийн тусламжтайгаар, цахилгаан соронзон индукц гэж нэрлэгддэг процессоор, оёдол эсвэл бусад металлын хэсгүүдийн оршин тогтнохыг илрүүлэх өндөр мэдрэмжтэй талбайг бий болгох боломжтой. Хэрэв гадаад объект агуулсан бүтээгдэхүүн машин дотор дамжвал, түүнийг дарж, шууд шалгах боломжтой болгохын тулд дохиолол дуугарна.

Нэгдэл ба захиалгат тохиргоо

Ywan Test-ийн зүү шалгах машинуудыг одоогийн үйлдвэрлэлийн процесс руу оруулахад хялбар байдал нь түүний хүчтэй талуудын нэг юм. Машинууд нь хэрэглэгчдэд ээлтэй бөгөөд интерфейс нь хялбархан навигац хийх боломжтой тул тохиргоонууд нь янз бүрийн салбарууд болон үйлдвэрлэлийн системүүдийн тодорхой шаардлагын дагуу тохируулагдсан байна. Энэ нь чанарын шалгалтуудыг үйлдвэрлэлийн процессыг томоохон зогсолтгүйгээр үр дүнтэй хийх боломжтой гэсэн үг юм.

Үйл ажиллагааны үр ашиг

Ywan Test-ийн зүү шалгах машинуудын хүчтэй шалтгаан нь тэдгээрийн үйл ажиллагааны үр ашиг юм. Эдгээр машин нь их хэмжээний бүтээгдэхүүнийг хурдан боловсруулж чаддаг бөгөөд энэ нь салбарын үйлдвэрлэлийн шугамд шаардлагатай арга хэмжээг авч хэрэгжүүлэхийг баталгаажуулдаг, бүх зүйл чанарын хяналтын хатуу стандартуудыг дагаж мөрдөж байна. Хурд болон нарийвчлалын энэ давхар шаардлага нь хэрэглэгчийн аюулгүй байдлыг хязгаарлахгүйгээр үйлдвэрлэлийг ихэсгэхийг хүсч буй бизнесүүдэд маш чухал юм.

Тогтвортой практик ба хог хаягдлыг бууруулах

Бүтээгдэхүүний чанарыг хангахаас гадна, зүү шалгах машин нь тогтвортой байдлын практикд тусалдаг. Эдгээр машин нь үйлдвэрлэлийн мөчлөгийн үеэр бохирдсон барааг зөв тодорхойлж, салгах замаар хог хаягдлыг арилгах боломжтой. Энэ практик нь үйлдвэрлэл байгаль орчинд үзүүлэх сөрөг нөлөөг ихээхэн бууруулдаг. Энэ нь орчин үеийн үйлдвэрлэлийн сайн практик руу хийж буй алхам юм.

Дүгнэлт

Дүгнэхэд, Ywan Test-ийн зүү шалгах машин нь чанарыг баталгаажуулахад дэлхий дээрх хамгийн дэвшилтэт машинуудаас зарим нь юм. Машины хэрэглээ нь бохирдлыг тодорхойлох, арилгах боломжийг олгодог бөгөөд энэ нь эцсийн бүтээгдэхүүний хэрэглэгчдийн аюулгүй байдлыг хангаж, тогтоосон аюулгүй байдлын стандартуудыг дагаж мөрдөхийг баталгаажуулдаг. Чанар, аюулгүй байдлын хэрэгцээ нэмэгдэж байгаа бөгөөд үйлдвэрлэлийн процессод дэвшилтэт зүү шалгах машин нэвтрүүлэх шаардлага ч мөн адил нэмэгдэж байна. Ywan Test-тэй хамтран бид шинэ чанарын баталгаажуулалтын систем, процессуудын инновацийг хангах, дэмжих, хамтран ажиллах боломжтой.

Улаан мэдээ

Улаан мэдээ2024-05-22

2024-05-22

2024-05-22