Advanced detection technology for precise metal impurity removal

Handles both magnetic and non-magnetic metals (steel, stainless steel, aluminum, etc.)

High sensitivity: detects metals as small as 0.3mm

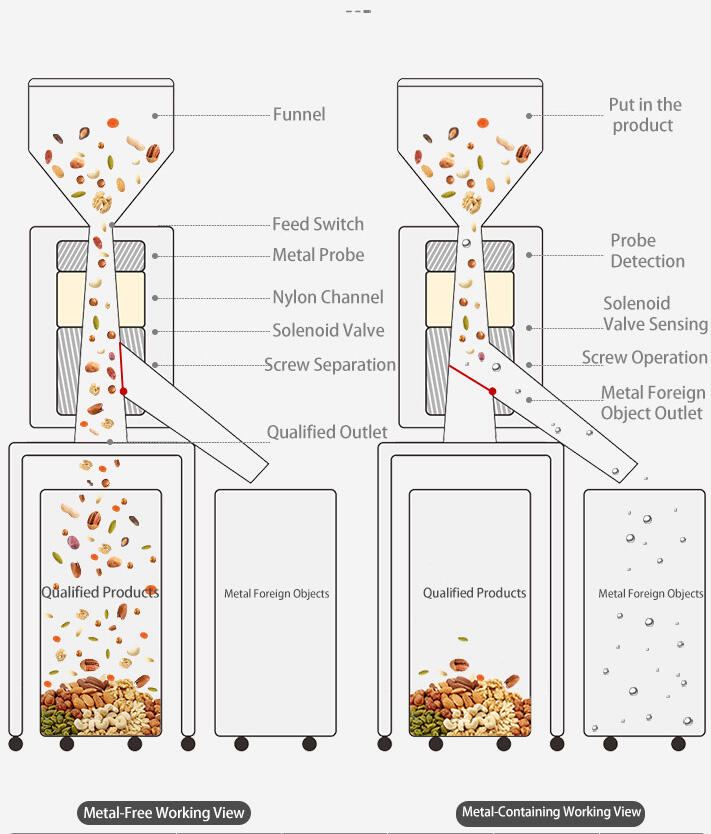

Fast response with 0.2-2.5 second separation time

Stepless adjustable detection accuracy (0-10 levels)

Microcomputer control with LED indication

Operating voltage: 220VAC ±10%

Protection levels: IP65 (controller), IP54 (machine)

Ambient temperature: -10°C to 60°C

Compressed air requirement: 4-8 kg, 0.4 liters per separation

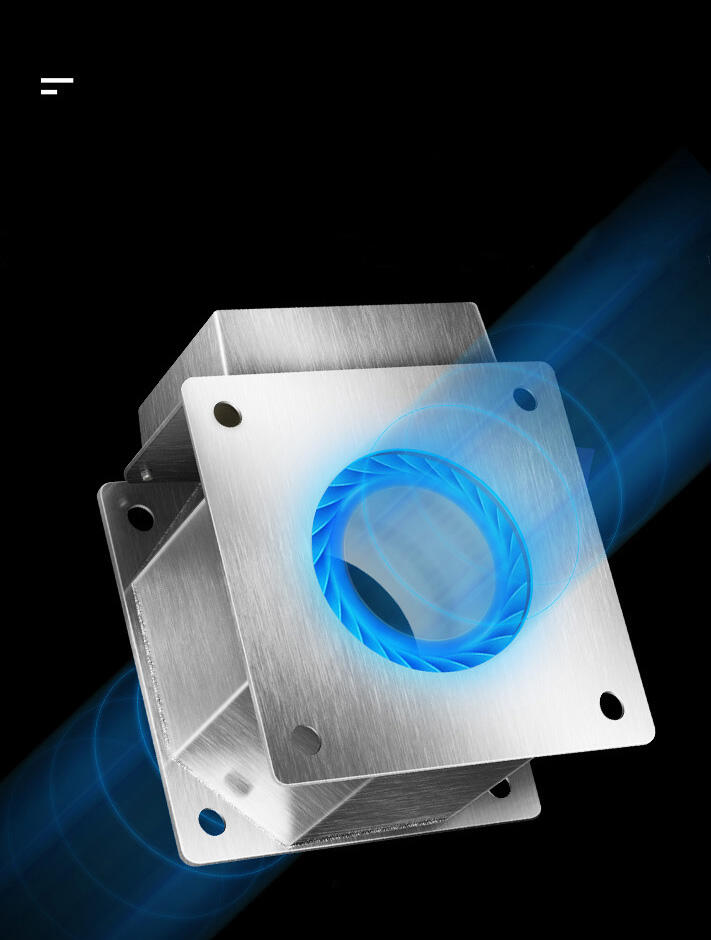

German imported detection system

German MEITLE control computer

Japanese SMC execution cylinder and gas filter

Painted steel plate housing

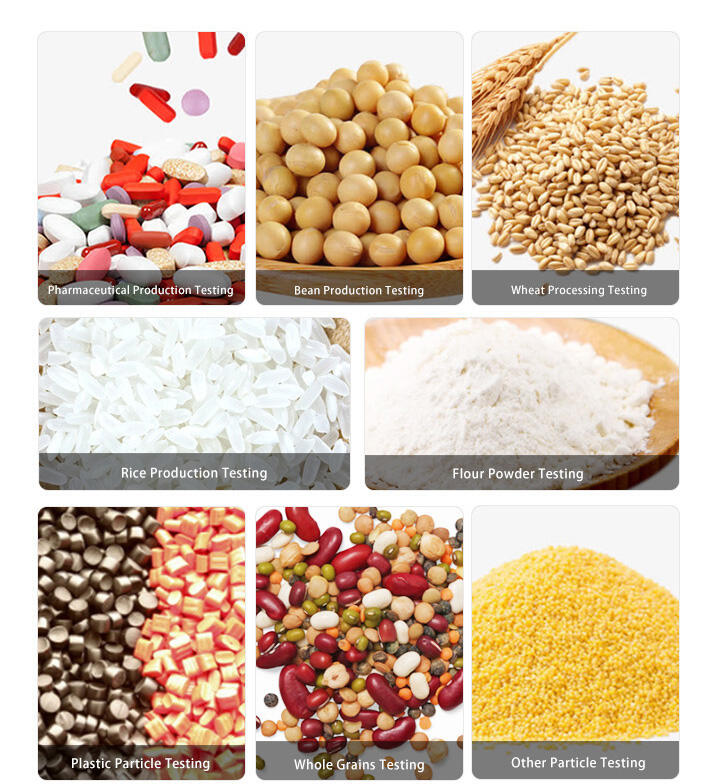

Food Industry: powders, granules, popcorn, chips, nuts, fruits, noodle soup

Chemical Industry: mixtures, carbon-containing additives

Plastics & Packaging: raw materials, pellets, nozzle materials

Non-clogging design handles long-fiber products

Prevents product agglomeration (ideal for light and thin materials)

Rustproof and waterproof discharge device

Easy cleaning with cleaning sheets

Compact size for direct equipment installation

Free-fall separation without product handling interference

Product Style/Parameters

| Inner Diameterof the Pipe(mm) | 30 |

50 | 70 | 100 | 150 |

| CQ-S01 Detection Accuracy (Fe ) | 0.3 | 0.3 | 0.7 | 0.8 | 1.2 |

| CQ-S01 Detection Accuracy (Sus ) | 0.5 | 0.5 | 1.0 | 1.2 | 1.5 |

| CQ-S02 Detection Accuracy (Fe ) | 0.3 | 0.5 | 0.7 | 1.0 | 2.0 |

| CQ-S02 Detection Accuracy (Sus ) | 1.0 | 1.2 | 1.5 | 2.0 | 3.5 |

| Maximum Processing capacity | 300~400kg/H | 700~800kg/H | 1000~1500kg/H | 2000~2500kg/H | 5000kg/H |

The inner diameter of the pipe can be customized according to requirements.

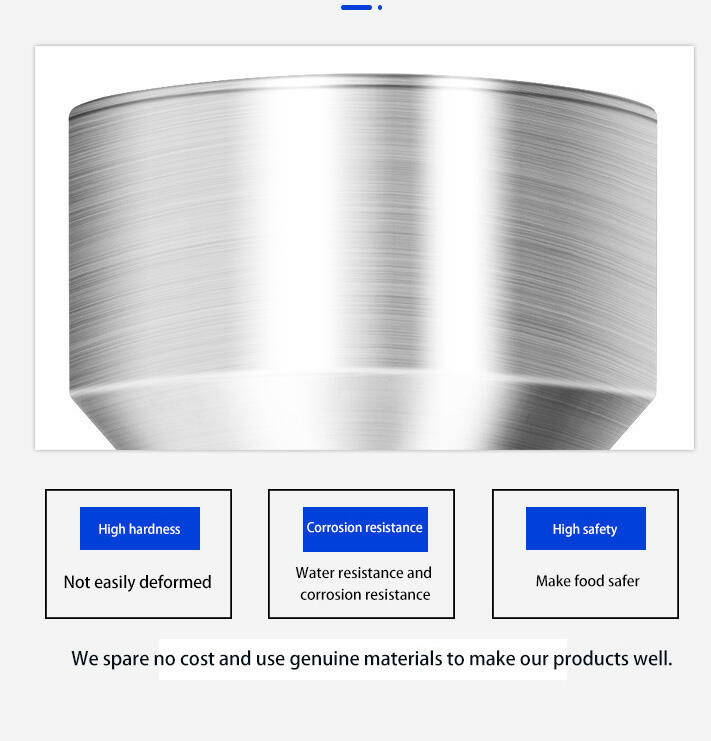

Stainless Steel Material

METAL SEPARATOR

Intelligent Separation/Multiple Calibers/High Detection Afcuracy/Strong Stability

PRODUCT FEATURES

Craftsmanship Quality Outstanding Performance

We use high-quality raw materials

It adopts high-quality 304 stainless steel,

featuring long durability,

water resistance and corrosion resistance.

High-precision detection probe

High-Precision Separation of Metal lmpurities

It can separate metal impurities from plastics, recycled materials, granular powders,

etc. with high precision.Rapid identification, capable of separating metal impurities of 0.3mm

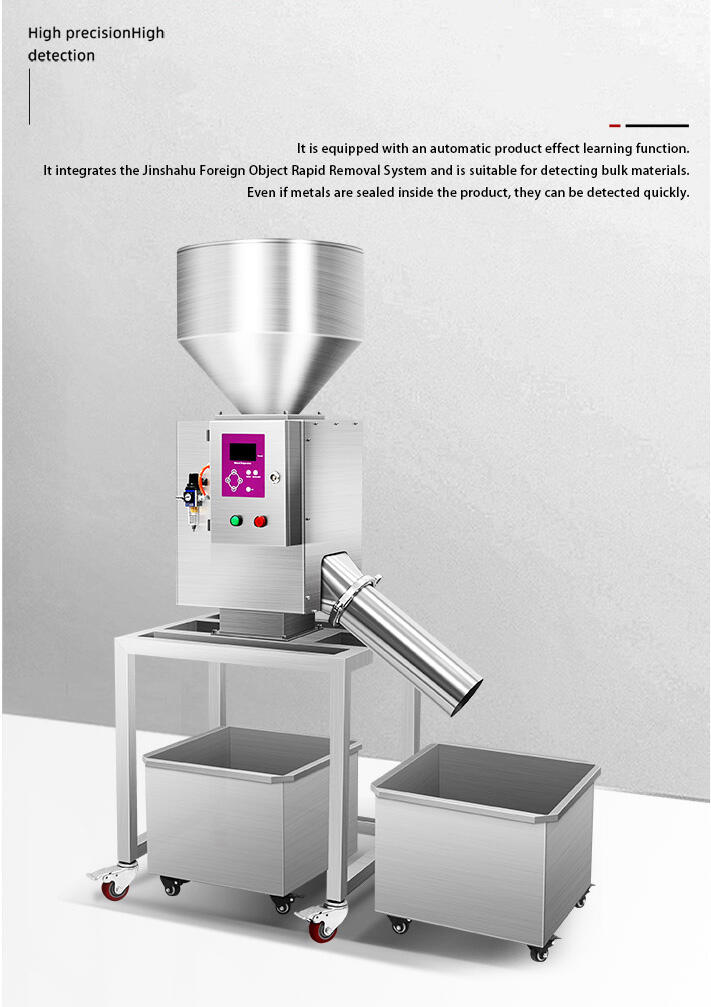

High precisiondetection

Intelligent Detection System

Leaving no metal undetected

End Time-Consuming and

Inefficient Manual Sorting

Industry-Specific Detedtion Scope

It is widely appllcable to pharmaceuticals, food, processing, vegetables, dalry products, etc.